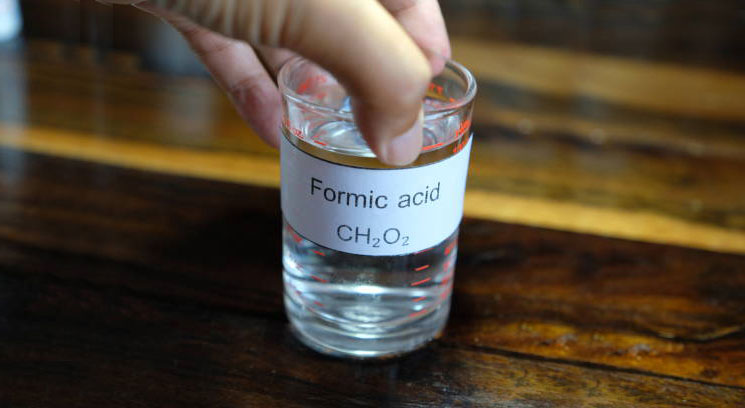

Formic Acid

Formic acid, ant essence or systematically methanoic acid, is the simplest carboxylic acid and has the chemical formula HCOOH. This substance is an important intermediate in chemical synthesis and is produced naturally. The word “formic” is derived from the Latin word for ant, formica, which indicates the distillation of the ant’s body. The ester, salt and anion of formic acid is called formate. Industrially, formic acid is produced from methanol.

History of formic acid

Some alchemists and naturalists knew that anthills gave off acid fumes as early as the 15th century. The first person to describe the isolation of this substance (by distillation of large numbers of ants) was the English naturalist John Ray in 1671. Ants secrete formic acid for attack and defense purposes.

Formic acid was first made by the French chemist Joseph Guy Lussac from hydrocyanic acid. In 1855, another French chemist, Marcelin Bertrelot, produced formic acid by synthesizing carbon monoxide.

Formic acid has long been considered a chemical compound of little interest in the chemical industry. By the late 1960s, significant quantities became available as a byproduct of acetic acid production. Now this substance has increased as a preservative and antibacterial agent in animal feed.

What is formic acid?

Formic acid is named after ants that have a high concentration of the compound in their venom. In ants, formic acid is derived from serine via an intermediate. Formic acid‘s conjugate base, formate, also occurs widely in nature. The method for measuring formic acid in body fluids, which is designed to determine formate after methanol poisoning, is based on the reaction of formate with bacterial formamide dehydrogenase.

Formic acid is flammable at a concentration of 85%. Formic acid contains 53 grams per liter of hydrogen at room temperature and atmospheric pressure, which is three and a half times what compressed hydrogen gas can achieve at a pressure of 350 bar. Pure formic acid is a liquid whose flash point is +69°C, much higher than that of gasoline (-40°C) or ethanol (+13°C).

Click on the link below to read more: